Hotline:

+84 934241168What is Business Intelligence? Business intelligence (BI) is the process of turning raw data into meaningful insights about your business performance to make better, more data-driven decisions. BI solutions include the tools, technologies, and practices that are used to collect, analyze, and organize your data to give you a comprehensive view of your organization, and […]

Business intelligence (BI) is the process of turning raw data into meaningful insights about your business performance to make better, more data-driven decisions. BI solutions include the tools, technologies, and practices that are used to collect, analyze, and organize your data to give you a comprehensive view of your organization, and allow you to use your data to drive change and eliminate inefficiencies.

BI covers a lot of processes and activities, including, for example, data mining, online analytical processing, performance metrics, querying, data visualization and reporting. To be able to smoothly perform these complex tasks, manufacturers or manager need to rely on software. This is especially applicable in manufacturing, which is actually one of the most data-intensive industries out there. The right BI tools will collect and filter this data, thereby analyzing the meaning of the data and helping manufacturers pull out actionable insights and make better business decisions

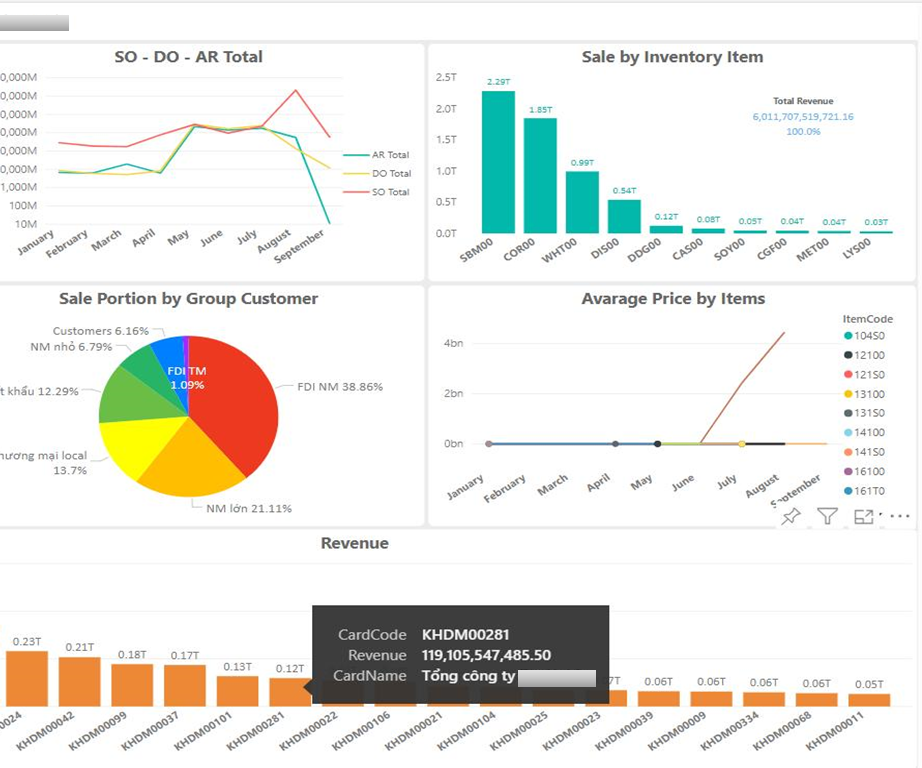

Sale dashboard (BI tools) of GA Advisor’s clients.

Currently most of the major manufacturing companies in the world have used ERP system to manage all their operations. With a management system acts as a central repository for all company data, BI makes it easy for manufacturers to improve their performance and operations. In the past manufacturers needed to comb through numerous spreadsheets and systems to pull out relevant data, and then analyze the data to create meaningful reports. But now, the right ERP will not only house all of your data in one place, but will have built-in BI tools to analyze data and create powerful reports to help manufacturers become more effective and productive.

And you don’t need to be a data scientist to understand the information ERPs will give you. With a quality ERP system, you can take advantage of a full range of reports at your fingertips—invaluable when it comes to analyzing operations—making it easier to keep on top of your key performance indicators (KPIs) and attaining your objectives. Live dashboards display all the information your organization needs to stay on top of your operations and make better decisions.

Business intelligence can help reduce operational inefficiencies, improve decision making, and boost productivity—ultimately letting you grow your business. Learning to use business intelligence to sift through and analyze your data will help you become a more efficient, leaner and more productive organization. Your data can show you where there are gaps or inefficiencies in your production line, and help you improve your manufacturing processes.

Data from live dashboards will give you all the information you need to set the right priorities to get jobs done and out the door on time. For example, through using dashboards that show real-time results, your production manager can keep a better eye on your shop floor, and make quick adjustments if, for example, a bottleneck occurs or the scrap rate becomes too high. Having access to real-time data gives decision-makers across your organization access to the data they need to make the best decisions they can to move your organization forward. BI can help improve your production scheduling, inventory control, financial management, and more.

BI also gives senior management the accurate facts, figures, and information they need to make strategic decisions and set your company in the right direction. Arguably the biggest factor in making good decisions is having access to the right data—data that you can get from your ERP’s built-in BI tools.

Using BI to improve your operations can have a major impact on your profit, setting you up for growth. ERP software that provides accurate, real-time information about daily operations help companies reduce operational costs by 23% and administration costs by 22% The bottom line: today’s most successful manufacturing businesses are built on a foundation of good, strong data.

If you are using an ERP to manage your custom manufacturing shop, you already have access to connected real-time data for your business. But, unfortunately, when it comes to BI and analytics, many enterprises still rely on manual processes and Excel spreadsheets to filter data and make critical decisions. Learning to use the built-in BI tools an integrated solution like an ERP has will make your business run smoother and more efficiently.

Failure to use BI strategy to guide your organization means you may be ignoring important market trends, failing to implement efficiencies that will let you remain competitive, and making poor strategic decisions. Many manufacturers have been sitting on reams of data coming out of their machinery and systems for years, but don’t know what to do with it. Learning to understand how to use this data, and mastering BI in your shop will set your organization up to be more effective, productive, and competitive.

Like many big changes, you will have to overcome resistance to change among employees to effectively roll out business intelligence tools in your organization. Maybe your general manager has been making important strategic decisions and setting the direction of your shop on gut instinct alone. Although she may have invaluable experience and knowledge about your company and industry, relying on gut instinct alone is risky.

GA Advisor gives employees training about BI

When implementing BI, you should first analyze the way you make decisions and consider what type of information executives and key decision-makers need to make faster, and more confident, decisions, as well as the best way to present the information (i.e. reports or dashboards). These discussions about the type of information you need to improve operations will drive what data you need to collect and analyze.

Like many technology projects, you won’t reap the benefits of business intelligence if users feel threatened by, or are skeptical of, the technology and refuse to use it as a result. Ensure you have key stakeholders, and a project champion in place that can effectively facilitate the adoption of your new BI tools.

For many manufacturers, putting in place a BI strategy will involve learning to use and implement their ERP system to its full potential. Today’s ERPs have powerful built-in BI tools, so manufacturers need to take the time to learn the full capabilities of their system, and work closely with their ERP provider to take advantage of these dynamic tools. Once mastered you will be able to pull out valuable insights, create dynamic reports to better understand your business, make better business decisions, achieve your goals—and ultimately grow your business.

Get your business on the right track today by learning more about the benefits of GA Advisor data analytics and visualization tools. Contact us via the hotline or leave your information here, GA Advisor will contact you as soon as possible!

GA ADVISOR VIET NAM

Add: R.608, DMC Tower, 535 Kim Ma, Ngoc Khanh Ward, Ba Dinh District, Ha Noi City

EMAIL: info@gaadvisor.net

TEL: (84) 98 561 3952 | (+84) 24 2217 6060

Lasted news